We offer a wide range of

label embossing systems, from manual, single-label embossing machines to

fully automatic programmable systems.

Several models for high capacity and low capacity labeling applications

All embossing machines are designed for use in industrial environments

Use a variety of label materials and sizes.

Automated Calender machines automatically receive information from the host system, fully integrated; manual machines provide portability.

Monday, July 17, 2017

Thursday, July 13, 2017

Other materials for calendering machines

When a smooth, flat surface is needed, such as cotton, linen, silk and various man-made fabrics and polymers such as vinyl and ABS polymer sheets, and to a lesser extent HDPE, calendering can also be applied to paper Outside the material, polypropylene and polystyrene.

The calender is also an important processing machine in the rubber industry, particularly the manufacture of tires, for the inner and fabric layers.

Calendering machine can also be used to polish or create evenly coated coatings on the substrate - the older use is to polish the tape, which is much faster than the web. More recently, it has been used to produce certain types of secondary batteries (such as spiral wound or prismatic lithium ion batteries) to achieve uniform thicknesses of the electrode material coating on the collector foil.

The calender is also an important processing machine in the rubber industry, particularly the manufacture of tires, for the inner and fabric layers.

Calendering machine can also be used to polish or create evenly coated coatings on the substrate - the older use is to polish the tape, which is much faster than the web. More recently, it has been used to produce certain types of secondary batteries (such as spiral wound or prismatic lithium ion batteries) to achieve uniform thicknesses of the electrode material coating on the collector foil.

Saturday, July 8, 2017

Calendering machine design

The key to the design of the two-roll open calender machine is roller structure, material selection and roller surface processing and technical parameter determination, followed by the configuration of the function. In the roller structure, we have adopted a different height of the large roller diameter in the rubber and plastic products industry, the height = (D-d) / 2, as shown in Figure 7. The purpose is to compensate for the rolling stress caused by the rolling deformation of the roll and improve the rolling part of the rolling force, forced magnetic particles to both sides of the flow, while for rolling may take different roll heating, respectively, designed for steam heating Of a hollow roll and a peripheral bore roll adapted for oil heating and water heating.

Through the production practice, the two kinds of heating methods can meet the process of roller surface temperature fluctuations in the error requirements. In the material selection, we use good wear resistance, rigidity of the alloy chilled cast iron material, roll face hardness HS72 ~ 75. But the alloy chilled cast iron roll is often due to casting defects and additives in the pellets may be on the roller surface corrosion, resulting in a short time after the use of roller surface "ice-like clouds", can not be pressed out of the smooth surface of the magnetic plate, thus It is necessary to carry out special treatment of the roller surface. Special treatment mainly has surface spray wear-resistant materials and hard chrome plating in two ways, we are using the latter.

To enhance the hard chrome and alloy chilled cast iron bonding strength, chrome before the need to first nickel, grinding processing, the thickness of the chrome layer is generally 0.05 ~ 0.08mm. It should be noted that in the production of PVC film coated with a side, the horizontal two-roll calender is best configured as a chrome-plated roller and the other is an alloy chilled cast iron roll. As the alloy chilled cast iron roll surface of the magnetic plate is relatively rough, is conducive to enhance the bonding strength of PVC film and magnetic plate.

Through the production practice, the two kinds of heating methods can meet the process of roller surface temperature fluctuations in the error requirements. In the material selection, we use good wear resistance, rigidity of the alloy chilled cast iron material, roll face hardness HS72 ~ 75. But the alloy chilled cast iron roll is often due to casting defects and additives in the pellets may be on the roller surface corrosion, resulting in a short time after the use of roller surface "ice-like clouds", can not be pressed out of the smooth surface of the magnetic plate, thus It is necessary to carry out special treatment of the roller surface. Special treatment mainly has surface spray wear-resistant materials and hard chrome plating in two ways, we are using the latter.

To enhance the hard chrome and alloy chilled cast iron bonding strength, chrome before the need to first nickel, grinding processing, the thickness of the chrome layer is generally 0.05 ~ 0.08mm. It should be noted that in the production of PVC film coated with a side, the horizontal two-roll calender is best configured as a chrome-plated roller and the other is an alloy chilled cast iron roll. As the alloy chilled cast iron roll surface of the magnetic plate is relatively rough, is conducive to enhance the bonding strength of PVC film and magnetic plate.

Wednesday, July 5, 2017

GUANGYU Calendering machine boot steps

Calender machine boot steps:

1, open the hot oil system

2, check the roller drive to meet the operational requirements.

3, use the console, control panel or control cabinet to open the drive.

4, use the console, control panel or control cabinet to open the paper drive.

5, the transmission from the speed control, to ensure that the speed difference between the roller is correct.

6, check whether you can start drawing paper.

7, lead the paper after the lead, check the work of the scanner, and check whether the open paper control is open.

8, check whether the calendering machine can be closed.

9, press the "CLOSE" closed nip, NIP will occur after the following conditions:

A calender will load the minimum set line pressure.

B The drive is controlled by tension.

10. Press the "LOADING" button to select the calender to load. The calender load is controlled by the set value.

11, at the same time, the following checks:

A Scraper is closed and swung.

B Temperature is set correctly.

C load set correctly 1, open the hydraulic system, lubrication system

(1) Nip control: The nip can be realized by the on-site operation buttons "NIP OPEN", "NIP RELIEFE" and "NIP LOAD". When the nip is closed, press the "NIP RELIEFE" button. When the signal is no longer flashing, press the "NIP LOAD" button to load the nip.

(2) Scraper control The upper and lower scraper control is achieved through the on-site switch.

1, open the hot oil system

2, check the roller drive to meet the operational requirements.

3, use the console, control panel or control cabinet to open the drive.

4, use the console, control panel or control cabinet to open the paper drive.

5, the transmission from the speed control, to ensure that the speed difference between the roller is correct.

6, check whether you can start drawing paper.

7, lead the paper after the lead, check the work of the scanner, and check whether the open paper control is open.

8, check whether the calendering machine can be closed.

9, press the "CLOSE" closed nip, NIP will occur after the following conditions:

A calender will load the minimum set line pressure.

B The drive is controlled by tension.

10. Press the "LOADING" button to select the calender to load. The calender load is controlled by the set value.

11, at the same time, the following checks:

A Scraper is closed and swung.

B Temperature is set correctly.

C load set correctly 1, open the hydraulic system, lubrication system

(1) Nip control: The nip can be realized by the on-site operation buttons "NIP OPEN", "NIP RELIEFE" and "NIP LOAD". When the nip is closed, press the "NIP RELIEFE" button. When the signal is no longer flashing, press the "NIP LOAD" button to load the nip.

(2) Scraper control The upper and lower scraper control is achieved through the on-site switch.

Thursday, June 22, 2017

Embossing machine and printing machine difference?

The printing machine is to print the pattern to paper, and then need to transfer in the printing machine to complete.

Embossing machine is needed to do the template, and then press out under a certain pressure.

Embossing machine is needed to do the template, and then press out under a certain pressure.

Tuesday, June 20, 2017

The basic information of the calender machine

The calender is mainly used for the pressing of the compound, the

hanging of the textile, the hanging of the steel cord, the rubber embryo

pressure type, the film fitting, the impurities in the compound and the

isolation film.classification

⑴ by use classification: calendering machine can be divided into the use of compression table rolling machine, rubbing calendering machine, tablet crimping machine, paste calender, pressure calender, calendering calendar and experimental calender.

⑵ according to the number of roller classification: rolling machine according to the number of rollers can be divided into two-roll calender, three-roll calendering machine, four-roll calender and five-roll calender.

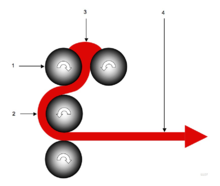

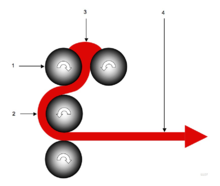

⑶ by roller arrangement classification: rolling machine in the form of roller can be I-shaped calender, △-calender, L-shaped calender, г-shaped calender, Z-calender, S-calender.Specification

Roller outer diameter (mm) × Roller face length (mm) × Roll number. Such as φ230 × 635 × 4, said roller diameter of 230mm, roller length of 635mm four-roll calender. Since the ratio of the diameter and length of the calender roll has been specified (i.e., the aspect ratio is between 2.6 and 3), the specifications of the calender can be expressed only by the length of the roll and in the form of a letter.

The model is shown as XY-4S-1800, where X is the rubber processing machine, Y is the calender, 4 is the number of rollers, S is the roll in the form of S-shape, and 1800 shows the length of the roller working part is 1800mm.

⑴ by use classification: calendering machine can be divided into the use of compression table rolling machine, rubbing calendering machine, tablet crimping machine, paste calender, pressure calender, calendering calendar and experimental calender.

⑵ according to the number of roller classification: rolling machine according to the number of rollers can be divided into two-roll calender, three-roll calendering machine, four-roll calender and five-roll calender.

⑶ by roller arrangement classification: rolling machine in the form of roller can be I-shaped calender, △-calender, L-shaped calender, г-shaped calender, Z-calender, S-calender.Specification

Roller outer diameter (mm) × Roller face length (mm) × Roll number. Such as φ230 × 635 × 4, said roller diameter of 230mm, roller length of 635mm four-roll calender. Since the ratio of the diameter and length of the calender roll has been specified (i.e., the aspect ratio is between 2.6 and 3), the specifications of the calender can be expressed only by the length of the roll and in the form of a letter.

The model is shown as XY-4S-1800, where X is the rubber processing machine, Y is the calender, 4 is the number of rollers, S is the roll in the form of S-shape, and 1800 shows the length of the roller working part is 1800mm.

Monday, June 19, 2017

What is a super calender machine?

Super calender is a kind of calendering equipment in papermaking. Shape similar to mechanical calender, but the number of rollers more. Applicable to coated paper, coated paper, writing paper, offset printing paper and other cultural paper and capacitor paper and other insulating paper.

Equipment structure

The equipment consists of a metal roller and a paper roll arranged vertically. Roll number of 5 to 12 roll, individual paper up to 15 to 20 rollers. The paper roll is made of high-pressure, such as sulphate wood pulp, cotton, wool, hemp and asbestos. Operation, due to the number of rollers, the line pressure, paper roll deformation of the paper to produce friction to further improve the paper gloss, smoothness and tightness. Super calender speed faster, more than one use. Generally also equipped with a retractable paper tray, reel and special lift platform and other ancillary devices. Used for finishing paper such as writing paper, offset printing paper, coated paper and capacitor paper.

The main function

In addition to cold cast iron roll, about half of the paper roll, wool, rags or asbestos as raw material made of paper roll paper, strong and strong, and flexible. Normally the bottom roller is the driving roller, and the other rollers are rotated by the friction between the rollers. The sheet is rolled to significantly enhance the gloss and smoothness of the paper and improve the appearance. In the machine on the basis of pressure to further improve the paper smoothness and gloss, while increasing the tightness and improve the thickness of the uniformity of the process for the super-Calender machine.

Equipment structure

The equipment consists of a metal roller and a paper roll arranged vertically. Roll number of 5 to 12 roll, individual paper up to 15 to 20 rollers. The paper roll is made of high-pressure, such as sulphate wood pulp, cotton, wool, hemp and asbestos. Operation, due to the number of rollers, the line pressure, paper roll deformation of the paper to produce friction to further improve the paper gloss, smoothness and tightness. Super calender speed faster, more than one use. Generally also equipped with a retractable paper tray, reel and special lift platform and other ancillary devices. Used for finishing paper such as writing paper, offset printing paper, coated paper and capacitor paper.

The main function

In addition to cold cast iron roll, about half of the paper roll, wool, rags or asbestos as raw material made of paper roll paper, strong and strong, and flexible. Normally the bottom roller is the driving roller, and the other rollers are rotated by the friction between the rollers. The sheet is rolled to significantly enhance the gloss and smoothness of the paper and improve the appearance. In the machine on the basis of pressure to further improve the paper smoothness and gloss, while increasing the tightness and improve the thickness of the uniformity of the process for the super-Calender machine.

Thursday, June 15, 2017

How does the four-roll Calender Machine work?

There are four rollers of the calender machine, roller arrangement in the form of T-type, L-type, S-type and Z-type, with high efficiency, high precision.

In the rubber industry is mainly used for the fabric of the adhesive, the steel cord of the paste, the pressure of the compound, the rubber blank, paste the film and multi-layer film and so on. Z-type roller which arranged a reasonable, can reduce the elastic deformation of the roller, easy to feed, so the application of a wider.

Working principle:

One of the necessary working conditions for the calendering process: the friction angle of the compound and the roller must be greater than the contact angle α, and the compound will be pulled into the roll. In the process of rolling, the roller is operated at a certain speed ratio, further kneading and increasing the plasticity of the compound, and finally rolling through the minimum roll distance into a film having a certain thickness and width ; In the roller squeeze force, the film squeeze in the textile or steel cord. Some need to be pressed into a certain pattern and shape, and some need to be multi-layer use, color, and shape of the film together.

In the rubber industry is mainly used for the fabric of the adhesive, the steel cord of the paste, the pressure of the compound, the rubber blank, paste the film and multi-layer film and so on. Z-type roller which arranged a reasonable, can reduce the elastic deformation of the roller, easy to feed, so the application of a wider.

Working principle:

One of the necessary working conditions for the calendering process: the friction angle of the compound and the roller must be greater than the contact angle α, and the compound will be pulled into the roll. In the process of rolling, the roller is operated at a certain speed ratio, further kneading and increasing the plasticity of the compound, and finally rolling through the minimum roll distance into a film having a certain thickness and width ; In the roller squeeze force, the film squeeze in the textile or steel cord. Some need to be pressed into a certain pattern and shape, and some need to be multi-layer use, color, and shape of the film together.

Tuesday, June 13, 2017

The calendering part of the paper machine

The calender part of the paper machine consists of a calender and other equipment. The paper runs between the plates to further smooth, which also makes it more even thickness. The pressure applied to the web by the rollers determines the finish of the paper and the paper has three types of finish.

The first is the calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

The first is the calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

Monday, June 12, 2017

How are the parameters of the calender developed?

The principle of

the design of the calender design is to achieve as much as possible a

calendering production of qualified magnetic plates. After

repeated multi-pass rolling of the magnetic plate of its internal

residual stress is large, and PVC film bonding, due to the difference

between the two shrinkage, there will be PVC film and magnetic

degumming, magnetic plate edge exposed PVC film and magnetic plate is

not flat And so on.

Through the calculation and experimental correction, we determined the production of less than 1000mm width of the magnetic plate Calender machine the best technical parameters: roll aspect ratio of 2.5 to 3, the height of the roll diameter of 0.1 to 0.3 ‰, roll line speed ≤ 3.5 M / min, roll surface temperature 60 ~ 80 ℃, speed ratio of 1: 1, and equipped with scraping device, roller surface temperature and roll gap display device.

There are different views on the roll ratio selection, and it is believed that the shearing force of a roll with a smaller speed ratio (eg, 1: 1.03) facilitates further plasticization of the pellets during calendering. In fact, this plasticization is extremely small, but because of the roll of the shear caused by the magnetic surface of the magnetic plate caused by rubbing and the expansion of small defects.

Through the calculation and experimental correction, we determined the production of less than 1000mm width of the magnetic plate Calender machine the best technical parameters: roll aspect ratio of 2.5 to 3, the height of the roll diameter of 0.1 to 0.3 ‰, roll line speed ≤ 3.5 M / min, roll surface temperature 60 ~ 80 ℃, speed ratio of 1: 1, and equipped with scraping device, roller surface temperature and roll gap display device.

There are different views on the roll ratio selection, and it is believed that the shearing force of a roll with a smaller speed ratio (eg, 1: 1.03) facilitates further plasticization of the pellets during calendering. In fact, this plasticization is extremely small, but because of the roll of the shear caused by the magnetic surface of the magnetic plate caused by rubbing and the expansion of small defects.

Friday, June 9, 2017

GUANGYU high quality Calendering machines and iron rod processing machines

Calender is a machine that stretches rubber or plastic to a certain thickness and surface shape at a certain temperature and can be used to hang the fiber curtain or steel cord. Usually consists of two or more rollers, arranged in a certain form. According to the number of rollers can be divided into two rollers, three rollers, four rollers and five roller calender, etc .; according to the arrangement of the roller can be divided into "L" type, "T" type, "F" Z "type and" S "type.

The principle of the design of the Calender machine is to achieve as much as possible a calendering production of qualified magnetic plates. After repeated multi-pass rolling of the magnetic plate of its internal residual stress is large, and PVC film bonding, due to the difference between the two shrinkage, there will be PVC film and magnetic degumming, magnetic plate edge exposed PVC film and magnetic plate is not flat And so on. Through the calculation and experimental correction, we determined the production of less than 1000mm width of the magnetic plate calender the best technical parameters: Roll aspect ratio of 2.5 to 3, the height of the roll diameter of 0.1 to 0.3 ‰, roll line speed ≤ 3.5 M / min, roll surface temperature 60 ~ 80 ℃, speed ratio of 1: 1, and equipped with scraping device, roller surface temperature and roll gap display device.

There are different views on the roll ratio selection, and it is believed that the shearing force of a roll with a smaller speed ratio (eg, 1: 1.03) facilitates further plasticization of the pellets during calendering. In fact, this plasticization is extremely small, but because of the roll of the shear caused by the magnetic surface of the magnetic plate caused by rubbing and the expansion of small defects.

The principle of the design of the Calender machine is to achieve as much as possible a calendering production of qualified magnetic plates. After repeated multi-pass rolling of the magnetic plate of its internal residual stress is large, and PVC film bonding, due to the difference between the two shrinkage, there will be PVC film and magnetic degumming, magnetic plate edge exposed PVC film and magnetic plate is not flat And so on. Through the calculation and experimental correction, we determined the production of less than 1000mm width of the magnetic plate calender the best technical parameters: Roll aspect ratio of 2.5 to 3, the height of the roll diameter of 0.1 to 0.3 ‰, roll line speed ≤ 3.5 M / min, roll surface temperature 60 ~ 80 ℃, speed ratio of 1: 1, and equipped with scraping device, roller surface temperature and roll gap display device.

There are different views on the roll ratio selection, and it is believed that the shearing force of a roll with a smaller speed ratio (eg, 1: 1.03) facilitates further plasticization of the pellets during calendering. In fact, this plasticization is extremely small, but because of the roll of the shear caused by the magnetic surface of the magnetic plate caused by rubbing and the expansion of small defects.

Monday, June 5, 2017

Double - head hydraulic foot - foot high - frequency machine product performance and characteristics

(1) spark suppressor: When the spark is generated, the machine is equipped with a special electronic circuit, can automatically cut off the high frequency of suppression of sparks, so that the damage to the mold and material to a minimum warning lights also light warning.

(2) to avoid radio interference device: a high frequency of high frequency stability and high frequency magnetic leakage trap device, this device can remove the radio leakage of electronic devices, such as television.

(3) Safety device: When the current exceeds the limit value, the overload current relay automatically protects the oscillation tube and the rectifier. When the mechanical cooling is insufficient, it can automatically cut off the power supply and avoid the accident caused by improper operation.

(4) mechanical structure special: the models through a special design and assembly, its strength enough to cope with any situation, the base is not shaking and the special part of the use of very light and accurate.

(5) easy to adjust the homogenizer and special circuit: high-cycle power output is particularly strong, can be adjusted by the mold size and material thickness adjustment, especially the special high-cycle, high stability of the output, particularly high output rate Greatly reduce the necessary welding time, improve product quality and production.

Calender machine machine range

Applicable to PVC or containing more than 30% of any hard and soft leather, cloth type of welding, indentation needs, such as shoes, trademarks, stickers, raincoats, rainflies, umbrellas, purses, hand bags, stationery, Inflatable toys, inflatable toys, locks, hardware, tools, trademarks and other special hard shell vacuum packaging, with particular emphasis on the needs of customers, to design and construction of water, toys, cushions, car, The

Double-head hydraulic foot pedal high frequency machine product advantages

Innovative models: the first combination of machine tools and oscillation, in a limited space can reduce the 30% of the machine one area, but also shorten the high frequency transmission loop to improve output efficiency and the most stable oscillation frequency.

High-performance models: the overall innovation design, with ergonomics and expertise to make the machine in dealing with various types of plastic products, can play its performance will not be due to the operation of the proficiency and reduce the quality and safety.

Spark suppression and safety device: When the spark is generated, it can automatically cut off the high frequency loop to minimize the damage to the parts and objects and when the current overload, automatically cut off the oscillation tube and rectifier circuit, to avoid the frequency of improper operation drift.

Professional configuration design: to avoid improper operation, to prevent radio interference (such as television, etc.) and increase the mechanical efficiency, and work effectiveness.

Drive: oil pressure.

(2) to avoid radio interference device: a high frequency of high frequency stability and high frequency magnetic leakage trap device, this device can remove the radio leakage of electronic devices, such as television.

(3) Safety device: When the current exceeds the limit value, the overload current relay automatically protects the oscillation tube and the rectifier. When the mechanical cooling is insufficient, it can automatically cut off the power supply and avoid the accident caused by improper operation.

(4) mechanical structure special: the models through a special design and assembly, its strength enough to cope with any situation, the base is not shaking and the special part of the use of very light and accurate.

(5) easy to adjust the homogenizer and special circuit: high-cycle power output is particularly strong, can be adjusted by the mold size and material thickness adjustment, especially the special high-cycle, high stability of the output, particularly high output rate Greatly reduce the necessary welding time, improve product quality and production.

Calender machine machine range

Applicable to PVC or containing more than 30% of any hard and soft leather, cloth type of welding, indentation needs, such as shoes, trademarks, stickers, raincoats, rainflies, umbrellas, purses, hand bags, stationery, Inflatable toys, inflatable toys, locks, hardware, tools, trademarks and other special hard shell vacuum packaging, with particular emphasis on the needs of customers, to design and construction of water, toys, cushions, car, The

Double-head hydraulic foot pedal high frequency machine product advantages

Innovative models: the first combination of machine tools and oscillation, in a limited space can reduce the 30% of the machine one area, but also shorten the high frequency transmission loop to improve output efficiency and the most stable oscillation frequency.

High-performance models: the overall innovation design, with ergonomics and expertise to make the machine in dealing with various types of plastic products, can play its performance will not be due to the operation of the proficiency and reduce the quality and safety.

Spark suppression and safety device: When the spark is generated, it can automatically cut off the high frequency loop to minimize the damage to the parts and objects and when the current overload, automatically cut off the oscillation tube and rectifier circuit, to avoid the frequency of improper operation drift.

Professional configuration design: to avoid improper operation, to prevent radio interference (such as television, etc.) and increase the mechanical efficiency, and work effectiveness.

Drive: oil pressure.

Technical parameters of ultrasonic thread cotton

Model: NK-JM2012

Frequency: 15KHZ,

Output power: 12KW

Dimensions: 8000MM * 2000MM * 2300MM

Efficiency: 8-20M / MIN

Weight: 6800KG

Working Principle of Ultrasonic Gouxian Machine

The use of high-frequency vibration wave to two or more surface of the material to be welded, in the case of pressure, the material surface friction with each other to form a fusion between the molecular layer, the advantage is fast, energy saving, high fusion strength, Good conductivity, no spark, close to cold processing.

Sample of cotton thread

Cotton thread sample (6 photos)

Calender machine Features

1. Welding time is short, automatic ultrasonic suture needle and thread, eliminating the need for frequent needle for the trouble, the sewing speed is 5 to 10 times the sewing machine quilted, wide by the customer self-

2. As a result of no needles, to avoid the sewing process with broken needle in the material within the situation, eliminating the security risks, a new generation of safety and environmental protection products;

3. There is no traditional line stitching disconnection joints, strong sticky, embossed clear, the surface is more three-dimensional relief effect, the product is more high-end beautiful;

4. After processing products without pinholes do not seepage, more waterproof and warm effect;

5. The use of wheel mold, mold for easy, can be stitched out of the ever-changing and complex non-continuous and symmetrical patterns, but also in accordance with customer needs to develop a variety of flower-shaped pattern;

6. The machine automatically high degree of intelligence, assembly infrared automatic side of the system can automatically correct the layers of materials, so that the upper and lower suture material is always aligned state, low processing loss, the product is more stable and stable

Application of Ultrasonic Gouxian Machine

Panties, mattresses, mattresses, mattresses, mattresses, pillow covers, mattresses, mattresses, mattresses, tablecloths, curtains, curtains, , Furniture supplies, wardrobe, storage storage, tents wardrobe, washing machine cover sets, Mummy bags, bottle insulation barrels, electric blankets, cosmetic bags, suit sets, bed cabinets, sauna cover, shoes bag , PVC pool at the end and so on.

Frequency: 15KHZ,

Output power: 12KW

Dimensions: 8000MM * 2000MM * 2300MM

Efficiency: 8-20M / MIN

Weight: 6800KG

Working Principle of Ultrasonic Gouxian Machine

The use of high-frequency vibration wave to two or more surface of the material to be welded, in the case of pressure, the material surface friction with each other to form a fusion between the molecular layer, the advantage is fast, energy saving, high fusion strength, Good conductivity, no spark, close to cold processing.

Sample of cotton thread

Cotton thread sample (6 photos)

Calender machine Features

1. Welding time is short, automatic ultrasonic suture needle and thread, eliminating the need for frequent needle for the trouble, the sewing speed is 5 to 10 times the sewing machine quilted, wide by the customer self-

2. As a result of no needles, to avoid the sewing process with broken needle in the material within the situation, eliminating the security risks, a new generation of safety and environmental protection products;

3. There is no traditional line stitching disconnection joints, strong sticky, embossed clear, the surface is more three-dimensional relief effect, the product is more high-end beautiful;

4. After processing products without pinholes do not seepage, more waterproof and warm effect;

5. The use of wheel mold, mold for easy, can be stitched out of the ever-changing and complex non-continuous and symmetrical patterns, but also in accordance with customer needs to develop a variety of flower-shaped pattern;

6. The machine automatically high degree of intelligence, assembly infrared automatic side of the system can automatically correct the layers of materials, so that the upper and lower suture material is always aligned state, low processing loss, the product is more stable and stable

Application of Ultrasonic Gouxian Machine

Panties, mattresses, mattresses, mattresses, mattresses, pillow covers, mattresses, mattresses, mattresses, tablecloths, curtains, curtains, , Furniture supplies, wardrobe, storage storage, tents wardrobe, washing machine cover sets, Mummy bags, bottle insulation barrels, electric blankets, cosmetic bags, suit sets, bed cabinets, sauna cover, shoes bag , PVC pool at the end and so on.

Friday, May 26, 2017

How to use Mirror roller

First, between the unwinding device and the rewinding device is provided with a lightening frame, a frame roller is mounted on the frame, and a guide roller and a display roll are arranged on the frame of the mirror roll. The roller is provided with a cooling roller in the direction of the cloth coming out, and one or two press rollers cooperating with the mirror hot Mirror Roller are provided on the lightening frame, the support roller and the correction device are arranged on the periphery of the pressure roller, The felt is wrapped around the embossing roller, the support roller and the correction device, and the pressure regulating mechanism is provided at both ends of the pressure roller.

The light-emitting device is mainly used for the surface of artificial leather hot light, increase the surface of finished leather surface, increase the surface of the luster and brightness, but also can cause the leather surface pattern from the bright place, the bottom of the ditch at the end of the effect.

The artificial leather and mirror roll are fitted with a pressure roller in a heat-resistant felt for a large diameter super-mirror heating roller to adjust the surface effect of the artificial leather by adjusting the pressure, temperature and ironing time of the artificial leather.

The light-emitting device is mainly used for the surface of artificial leather hot light, increase the surface of finished leather surface, increase the surface of the luster and brightness, but also can cause the leather surface pattern from the bright place, the bottom of the ditch at the end of the effect.

The artificial leather and mirror roll are fitted with a pressure roller in a heat-resistant felt for a large diameter super-mirror heating roller to adjust the surface effect of the artificial leather by adjusting the pressure, temperature and ironing time of the artificial leather.

Wednesday, May 24, 2017

What is supercalendered paper?

The US International Trade Commission (USITC) today decided that the US industrial sector as a result of Canada's imports of high molecular weight paper Calender machine, the US Department of Commerce determined to be subsidized and seriously injured.

Chairman Meredith Bledberg, Vice President A. Pinkert, and Irving Williamson, David Johnson, and Rhonda K. Schmidtlein Commissioner voted for the vote. Scott Kiefer did not attend the survey.

Due to the USITC affirmative ruling, the Ministry of Commerce will issue a countervailing duty on Canada's imports of the product.

The Committee's public report from Canada's super-document (decision 701-TA-530 (final), USITC publication 4583, December 2015) will contain information provided by the Committee's observations and surveys.

The report will be available by December 24, 2015; when available, it may be accessed on the USITC website at: http://pubapps.usitc.gov/applications/publogs/qry_publication_loglist.asp.

Calender section of a paper machine

The calender part of the paper machine consists of a calender and other equipment. The paper runs between the plates to further smooth, which also makes it more even thickness. The pressure applied to the web by the rollers determines the finish of the paper and the paper has three types of finish.

The first is the Calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

The first is the Calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

Monday, May 22, 2017

Custom embossing rolls and embossing machines for paper and film markets.

The industrial engraving company serves all aspects of the embossing industry. Our

unparalleled technical knowledge and experience in solving the unique

customer needs in the paper, foil, paper towels, nonwovens, films,

rubber and plastics markets to ensure you the highest quality Metal embossing machine

and services today.

In industrial carving companies, we have a large number of processing centers, highly skilled and experienced mechanics, sculptors and the ability to create custom designs for our customers. From our in-house lab production line prototyping service to the timely delivery of multiple production lines and our expertise, industrial carving companies offer customers the advantage of introducing new products from a single source worldwide.

All of our industrial engraving companies are aware of the importance of supplying the product, and as we have asked our customers, we are determined to exceed our customers' expectations and push us to keep our customers loyal.

CALENDERING MACHINE With high Quality from GUANGYU

Description of GUANGYU CALENDERING MACHINE

On the current market conditions, this machine has been more and more customers to buy, not only because of its quality, and the use of relatively easy, compared to some of the old products are also constantly upgrading the upgrade.

Technical data (For Example)

1) Structure of Calender Machine: Vertical Type Two-roller Calender Machine;

2) Roller Size: 480x3600mm, pattern effective width:3580mm,final product≥3200mm;

3) Material Calender Roller: 42CrMoV;

4) Structure of Calender Roller: integral casting, peripheral drilling, hole diameter: 35mm,hole quantity:18 holes, drilling line degree (including connecting error ≤ 0.5mm);

5) Hardness of Calender Roller: HRC60 for smooth roller, HRC58 for embossing roller;

6) Roller pattern: up to the requirement of buyer;

7) Calender machine line pressure: 0~120kg/cm, adjustable,etc.

We make the calender machine according to your demand. We can satisfy your special requirement.

Welcome to our factory for visiting!

Subscribe to:

Comments (Atom)