First, between the unwinding device and the rewinding device is provided with a lightening frame, a frame roller is mounted on the frame, and a guide roller and a display roll are arranged on the frame of the mirror roll. The roller is provided with a cooling roller in the direction of the cloth coming out, and one or two press rollers cooperating with the mirror hot Mirror Roller are provided on the lightening frame, the support roller and the correction device are arranged on the periphery of the pressure roller, The felt is wrapped around the embossing roller, the support roller and the correction device, and the pressure regulating mechanism is provided at both ends of the pressure roller.

The light-emitting device is mainly used for the surface of artificial leather hot light, increase the surface of finished leather surface, increase the surface of the luster and brightness, but also can cause the leather surface pattern from the bright place, the bottom of the ditch at the end of the effect.

The artificial leather and mirror roll are fitted with a pressure roller in a heat-resistant felt for a large diameter super-mirror heating roller to adjust the surface effect of the artificial leather by adjusting the pressure, temperature and ironing time of the artificial leather.

Friday, May 26, 2017

Wednesday, May 24, 2017

What is supercalendered paper?

The US International Trade Commission (USITC) today decided that the US industrial sector as a result of Canada's imports of high molecular weight paper Calender machine, the US Department of Commerce determined to be subsidized and seriously injured.

Chairman Meredith Bledberg, Vice President A. Pinkert, and Irving Williamson, David Johnson, and Rhonda K. Schmidtlein Commissioner voted for the vote. Scott Kiefer did not attend the survey.

Due to the USITC affirmative ruling, the Ministry of Commerce will issue a countervailing duty on Canada's imports of the product.

The Committee's public report from Canada's super-document (decision 701-TA-530 (final), USITC publication 4583, December 2015) will contain information provided by the Committee's observations and surveys.

The report will be available by December 24, 2015; when available, it may be accessed on the USITC website at: http://pubapps.usitc.gov/applications/publogs/qry_publication_loglist.asp.

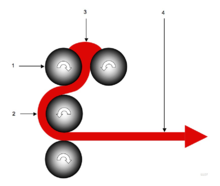

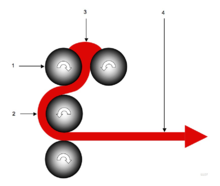

Calender section of a paper machine

The calender part of the paper machine consists of a calender and other equipment. The paper runs between the plates to further smooth, which also makes it more even thickness. The pressure applied to the web by the rollers determines the finish of the paper and the paper has three types of finish.

The first is the Calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

The first is the Calender machine finish, or MF paper, which can be made from rough / mute (matte), looks smooth and high quality finish.

The second is called Super Finishing or MG Paper (Machine Glaze), which is glossy / glazed and suitable for highly fine halftone printing.

The third type of finishes are called plating, and the first two types of finishes are achieved by the calender itself, by placing the cut paper between the stacked zinc or copper plates and then placing them in pressure and heating under. A special surface treatment of linen finish can be achieved by placing a linen between the plates and the paper, or an embossed roll can also be used.

After calendering, the water content of the web is about 6% (depending on the ingredients). Which is wound on a roll called a roller and stored for final cutting and transport.

Monday, May 22, 2017

Custom embossing rolls and embossing machines for paper and film markets.

The industrial engraving company serves all aspects of the embossing industry. Our

unparalleled technical knowledge and experience in solving the unique

customer needs in the paper, foil, paper towels, nonwovens, films,

rubber and plastics markets to ensure you the highest quality Metal embossing machine

and services today.

In industrial carving companies, we have a large number of processing centers, highly skilled and experienced mechanics, sculptors and the ability to create custom designs for our customers. From our in-house lab production line prototyping service to the timely delivery of multiple production lines and our expertise, industrial carving companies offer customers the advantage of introducing new products from a single source worldwide.

All of our industrial engraving companies are aware of the importance of supplying the product, and as we have asked our customers, we are determined to exceed our customers' expectations and push us to keep our customers loyal.

CALENDERING MACHINE With high Quality from GUANGYU

Description of GUANGYU CALENDERING MACHINE

On the current market conditions, this machine has been more and more customers to buy, not only because of its quality, and the use of relatively easy, compared to some of the old products are also constantly upgrading the upgrade.

Technical data (For Example)

1) Structure of Calender Machine: Vertical Type Two-roller Calender Machine;

2) Roller Size: 480x3600mm, pattern effective width:3580mm,final product≥3200mm;

3) Material Calender Roller: 42CrMoV;

4) Structure of Calender Roller: integral casting, peripheral drilling, hole diameter: 35mm,hole quantity:18 holes, drilling line degree (including connecting error ≤ 0.5mm);

5) Hardness of Calender Roller: HRC60 for smooth roller, HRC58 for embossing roller;

6) Roller pattern: up to the requirement of buyer;

7) Calender machine line pressure: 0~120kg/cm, adjustable,etc.

We make the calender machine according to your demand. We can satisfy your special requirement.

Welcome to our factory for visiting!

Subscribe to:

Comments (Atom)